| Product Features |

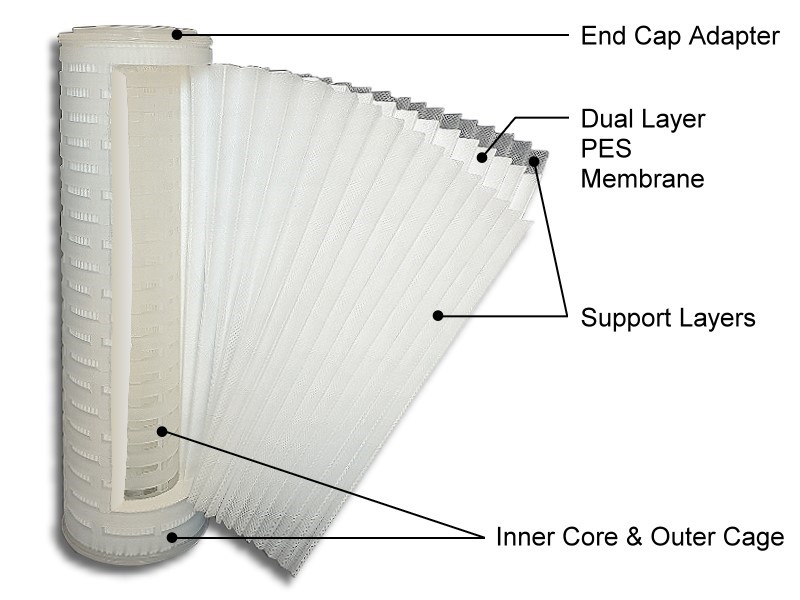

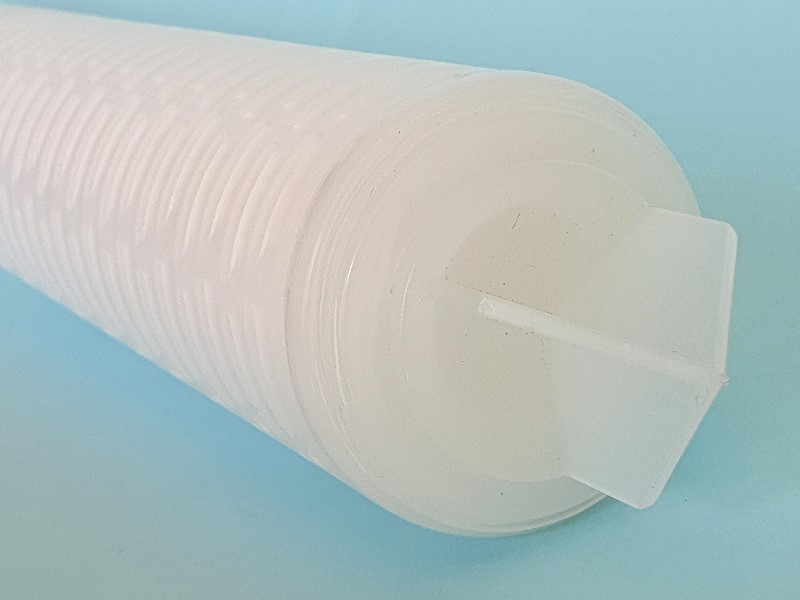

| Utilizes asymmetric, high-precision PES (Polyethersulfone) film, and its asymmetrical loose-tight-loose structure can effectively reduce piezoresistance, has high filtration efficiency for organic and inorganic particles, and prolongs the service life of the filter element. It is matched with polypropylene material The supporting material, inner and outer porous support pipes and upper and lower joints are made. The PES film itself has excellent chemical resistance and hydrophilicity. The assembly of the various parts of the filter element is completely thermally fused in a clean room environment without the use of adhesives, so there is no release of any additives, and it can be widely used Photoresist BOE etchant, Clean, DI water cycle filtration in semiconductor and optoelectronic industries and precision filtration in general food and beverage factories. |

| Operating conditions |

| Maximum operating pressure difference | - 1.4 kg/cm² (95°C)

- 5.5 kg/cm² (20°C)

|

| It is recommended to replace the pressure difference | 2.0 kg/cm² |

| Operating temperature | 95 °C |

| Filter area | 0.5 m² (10" filter element) |

| Description of filter element sterilization conditions | - Steam=121 °C/30 minutes/10 times

- Hot water = 80 °C/30 minutes/30 times

|

| Product specifications |

| Aperture | Absolute 0.05, 0.1, 0.2, 0.45, 0.65, 1, 1.2, um |

| Membrane material | Hydrophilic polyether sulfone PES (Polyethersulfone) film |

| Support material | Polypropylene |

| temperature | Maximum operating temperature 95℃ |

| Scope of application |

Terminal filtration of pharmaceuticals and biological products; terminal filtration of drinking water, beverages, ultra-pure water, wine, etc.; filtration of chemical raw materials

- Clean and Rinse process stage filtering in the optoelectronic industry.

- BOE, photoresist precision filtration.

- Precision filtration at the end of DI water.

- Fine filtration for the food and beverage industry.

|